Industry & Trade

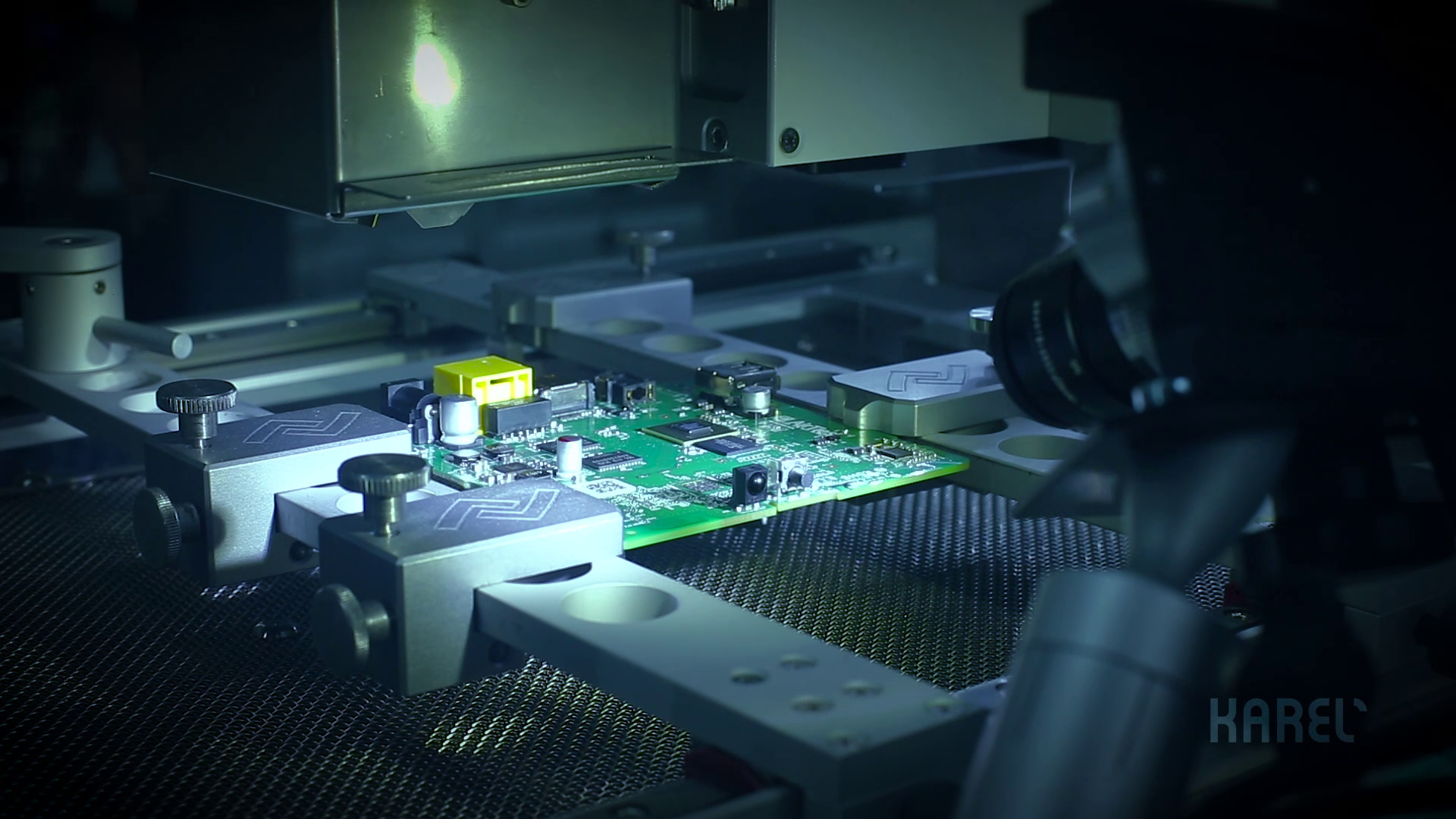

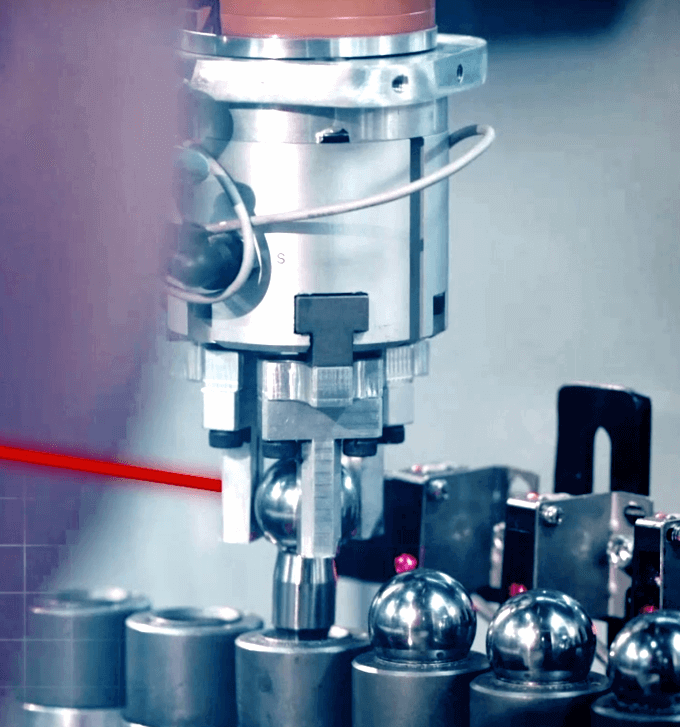

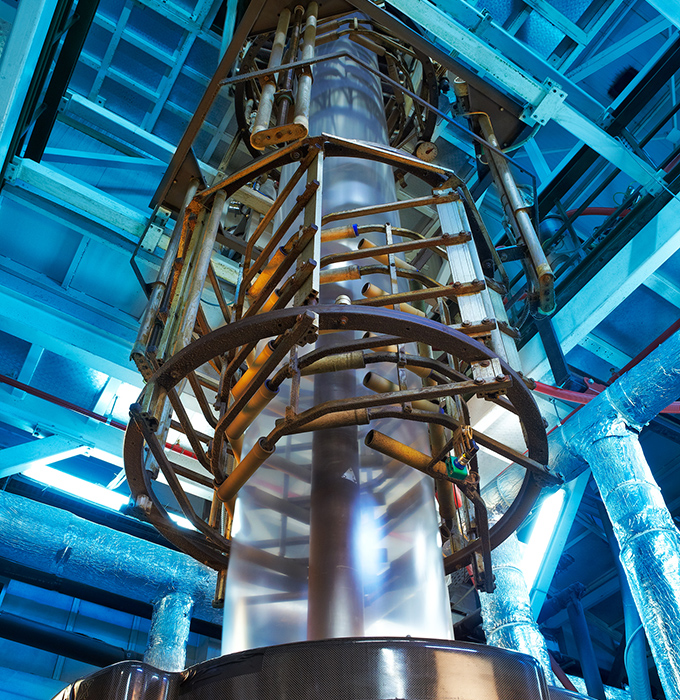

Our group companies’ innovative approach, R&D activities, quality emphasis and design prowess makes them stand out through the competition. While Ditaş uses cutting-edge technologies to produce a variety of industrial products in the field of automotive, defense and spare parts; Sesa focuses on the production of flexible packaging and barrier films. A fully-integrated technology company from design to production, Karel operates in the fields of telecom, defense industries, corporate projects, automotive projects, IoT projects and electronics manufacturing services.

Doğan Dış Ticaret

Operating primarily in the raw material supply business, Doğan Dış Ticaret (DDT) distributes paper, cardboard and packaging products. One of DDT’s main markets remains print media, such as newspapers, magazines and books, and it continually expands its portfolio to include new packaging and cardboard products. It serves as a solution partner, providing manufacturers with essential and reliable raw material.

Kelkit Doğan Besi

Established in 2002, Doğan Organik Süt Sığırcılığı İşletmesi produces organic milk while also creating a sustainable agricultural model to stimulate economic development in the region. Doğan Organik Süt Sığırcılığı İşletmesi altered its field of activity in 2018 by directly entering the cattle ranching business in an effort to even better sustain the region’s economic development.

The company, which adopted the name Kelkit Besi for its expansion into cattle, attaches great importance to the economic, social and cultural development of Kelkit, and encourages farmers in the region to produce products with the highest added value. As a result, farmers benefit both themselves and the economy of Kelkit. Kelkit Doğan Besi also aims to help eliminate the red meat deficit in Turkey.

Doğan Air

Doğan Air offers domestic and international air taxi transportation on its Falcon F2000LXS 2016 airplane, which has to date flown more than 8,000 hours. Since its inception in 2002, the aviation company has remained the first choice among the region’s most prominent business people.